Laser Cutting

We cut using the quickest and most precise tool there is – the laser.

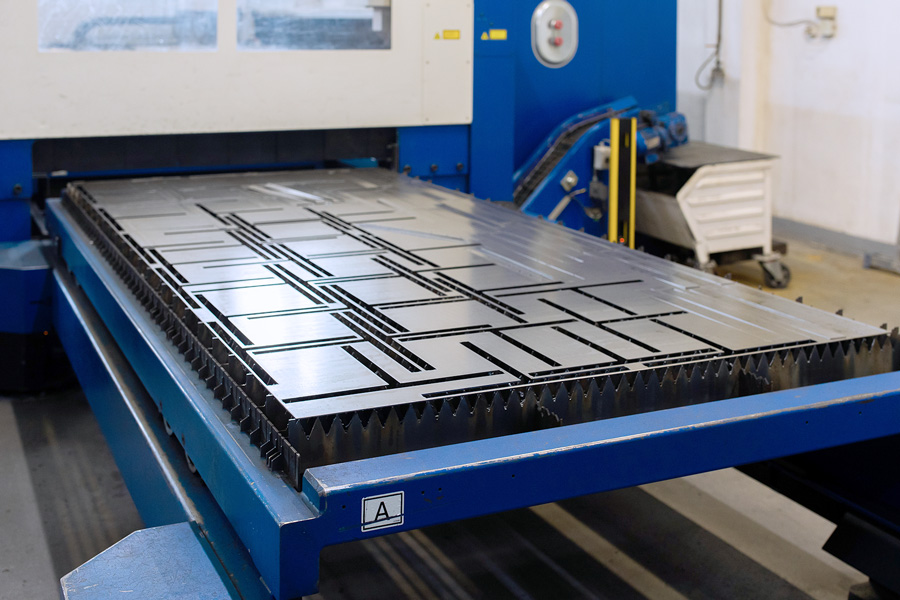

Cutting Through Thick and Thin

We utilize lasers to process steel, stainless steel, aluminum and non-ferrous metals, creating everything from individual parts to series productions. Owing to our state-of-the-art laser systems with CO2 and fiber laser technology, our edges are impeccable – and generally require no further finishing. The thinnest material we cut has a wall thickness of 0.1 mm. For sheet metal, thickness ranges from 0.5 to 25 mm.

Steel: 1.500 x 3.000 mm

Stainless Steel: 1.500 x 3.000 mm

Aluminum: 1.500 x 3.000 mm

Laser Cutting: Precision and Efficiency in any Shape

Our fully automated laser cutting systems cut quickly, cleanly and efficiently. High productivity combined with immediate availability using sheet metal from our own stock speeds up the process, reducing delivery times and saving money.

![[Translate to English:] Materialvielfalt, Edelstahl, Stahl, Aluminium, Messing, Kupfer Vielzahl an unterschiedlichen Materialien](https://www.kaysser-international.com/fileadmin/user_upload/01_HPK/Leistungen/Laserschneiden/Products/1800x1200-Laser-produkt-vielfalt2.jpg)

Unparalleled range of materials

Be it stainless or structural steel, aluminum or copper, brass or non-metals – our extensive pool of state-of-the-art laser cutting systems enables processing of a wide range of materials for all industry sectors. We also offer laser-cut parts from non-metallic materials upon request.

The Cutting Edge of Technology

The exceptional precision of our laser-cut parts is primarily thanks to our advanced laser-cutting technology. In combination with our well-trained and highly-motivated team, we can reliably produce laser parts according to German quality standards.

Additional Services

According to your needs, laser cutting can be complemented with additional steps such as deburring, straightening and bending and we also offer machining processes to complete your components. We can tailor the appropriate processes to your specific requirements.

Get in touch

We are happy to provide comprehensive information on our ability to produce ready-to-install workpieces. Our fully automated production enables us to process your orders efficiently. Urgent workpieces can be manufactured continuously over one or several shifts, depending on batch size.