Mechanical Processing

Versatile manufacturing processes for further processing.

Mechanical Processing complements our Range of Services

Mechanical processing functions as an addition to our laser cutting, welding and forming services. Be it deburring, drilling, countersinking, threading, sawing or pressing – we offer a variety of common post-processing steps for your components, seeing them through to the best result.

Deburring

Deburring removes burrs and splinters from the workpiece, thus ensuring a flawless final product. Mechanically processing metal parts invariably leads to discoloration and marks on a surface level, such as sharp edges or uneven areas. Our skilled professionals remove these marks using the latest technology.

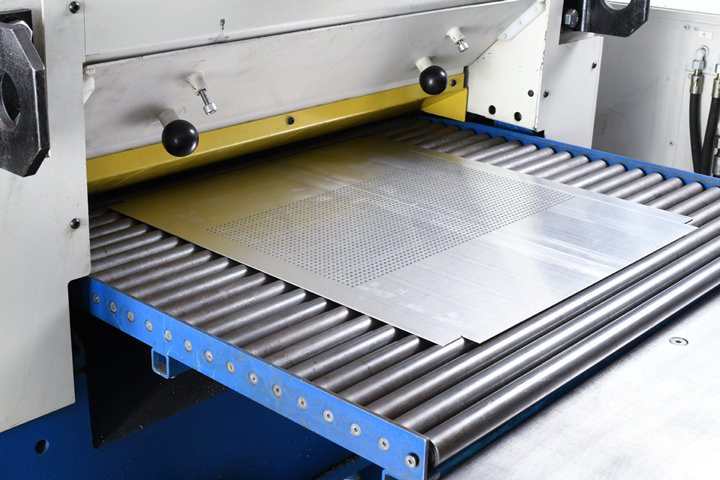

Straightening

Straightening is a process used to eliminate stresses and imperfections in the workpiece that could negatively affect subsequent processing. Employing the roll straightening method reduces stresses in the sheet metal and removes any unevenness.

Sawing

Sawing is a subtractive cutting process and an essential manufacturing technique for separating workpieces. Individual chips are separated by a series of sequentially arranged wedges, resulting in material removal along the cutting seam.

Drilling

Drilling is a subtractive manufacturing process used to create holes and openings in workpieces. Material is removed by rotary motion and feed force, creating a recess. We can drill parts of up to a diameter of 24 mm.

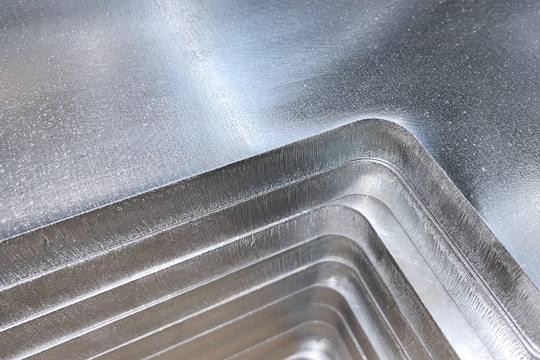

Countersinking

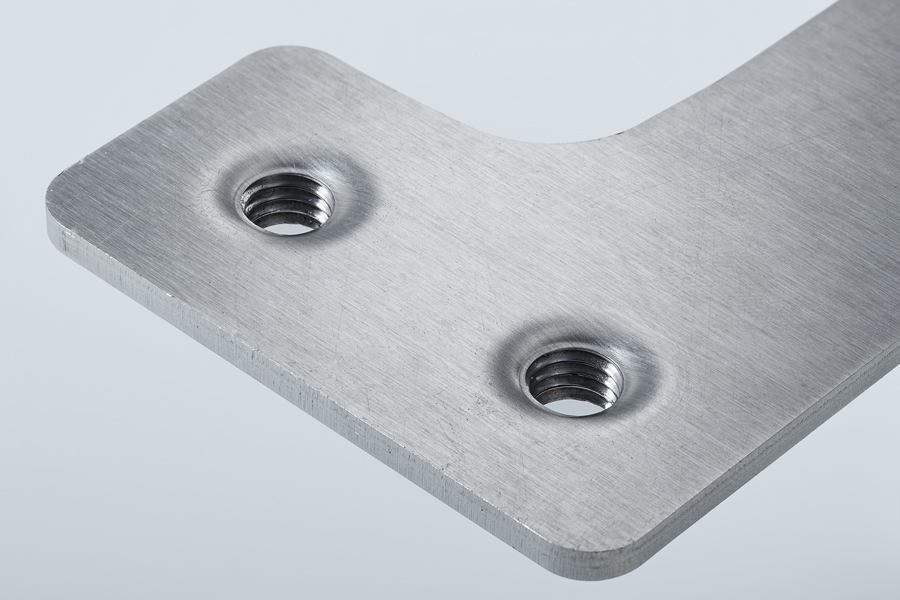

Countersinking is a drilling process employed to finish holes. A multi-edged tool, the counterbore, creates profiled or flat recesses through feed force and circular motion for standard parts like screws and nuts. The countersink ensures that, for example, the screw head is now flush with the workpiece surface.

Thread Cutting

Thread cutting is a drilling process used to create internal threads. A cutting tool, the screw tap, creates threads in the workpiece by applying feed force and circular motion.

Reaming

Reaming is a subtractive manufacturing process used to create precise holes with a high surface quality and both form and dimensional accuracy. Laser-cut openings are finished using a reamer.

Pressing

Pressing is a joining process that creates a permanent, form-fitting connection between workpieces without the use of additional joining materials. With significant force, bolts or nuts are pressed into a component to establish a form-fitting connection between the workpiece and the inserted object. We offer a wide variety of press-fit nuts and bolts.

Additional Services

We offer you cost-effective complete solutions at the highest quality level thanks to a high level of vertical integration. We cater to your individual requirements when selecting the processes.

Get in Touch

Together, we will find the optimal manufacturing solution for your components. Let our qualified experts consult you on our metal and sheet processing capabilities.