Oxy-Fuel Cutting

We cut large material thicknesses with utmost precision.

Big, bigger, XL – we‘re fired up about Oxy-Fuel Cutting

Autogenous Oxy-fuel cutting is one of the oldest but still among the most important cutting methods in metalworking industries. The oxy-fuel process has proven to be the optimal and most cost-effective solution for cutting low-alloy steels with a material thickness of 25 mm and up with precision and speed. There are currently no economical alternatives to the autogenous oxy-fuel cutting method for material thicknesses of 50 mm and up.

From prototypes and small batch sizes to repeat parts and series production, we can handle your orders. Thanks to our state-of-the-art CNC oxy-fuel cutting systems, we guarantee clean, high-precision cutting, complete with expert-level consultation and a thoroughly planned execution for all your orders.

Additional Treatment Options

We offer additional treatment options in conjunction with oxy-fuel cutting. Feel free to reach out if you have any questions regarding additional steps.

Annealing

The annealing process relieves internal stresses in the component that arise during cutting and welding. The additional step reduces these stresses without altering the material’s strength, laying the groundwork for further mechanical processing steps.

Shot Blasting

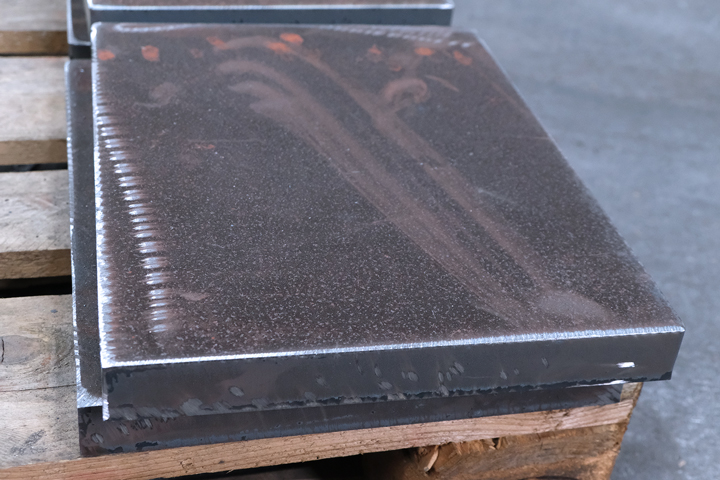

The shot blasting step is used to clean the oxidized surface caused by the annealing process. Shot blasting also serves as a preparatory step for subsequent processes, such as welding or painting.

Grinding

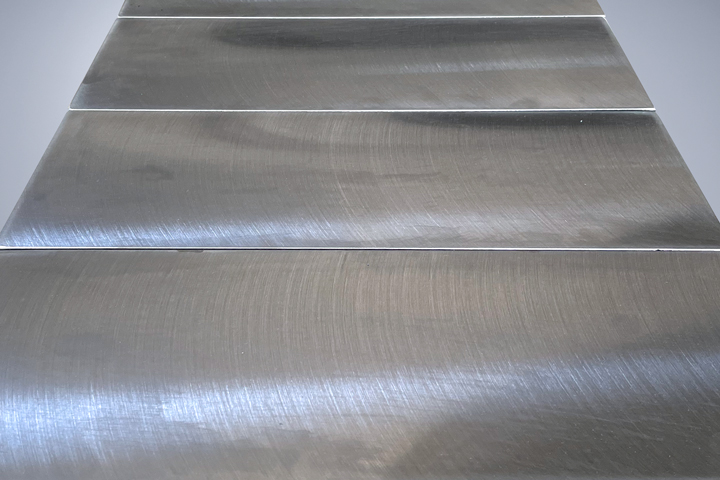

Disc grinding improves the surface quality of your parts and ensures a precision fit.

Additional Services

We offer additional processing steps to finalize your components. The selection is based on your specific requirements.

Laser cutting

Forming

Tube and Steel Structures

Welding

Surface Treatment

Module assembly

Mechanical Processing

Logistics + Shipping

Get in touch

We are happy to provide comprehensive information on our ability to produce ready-to-install workpieces. Our fully automated production enables us to process your orders efficiently. Urgent workpieces can be manufactured continuously over one or several shifts, depending on batch size.